Home » Production Line

Production Line

Arab Union Glass: A Legacy of Excellence

At Arab Union Glass, we take pride in our cutting-edge production lines that enable us to manufacture a wide range of high-quality glass products. From precision cutting to advanced laminating and tempering techniques, each production line is designed to meet the diverse needs of our clients across various industries. Whether you're looking for curved glass for architectural projects or insulated glass for energy-efficient buildings, our state-of-the-art facilities and skilled team ensure that we deliver superior glass solutions that set industry standards for safety, durability, and innovation.

Heat Soak Line

We provide the prestigious Heat Soak Test (HST) in our factories!

This rigorous testing process simulates the effects of long-term exposure to high temperatures, allowing Arab Union Glass to identify Nickel Sulfide in glass panels before they are installed with a detailed reporting graph and information.

Insulating Glass Line

It is the newest line in the Middle East, as it has the ability to implement areas up to 3.5 meters high, 2.44 meters width It also has the ability to inject gas automatically in addition to a robot to do the final injection, which reduces the intervention of the manual operator.

Laminated Glass Line

It is the newest line in the Middle East in operating areas, as it can implement a block measuring 6 m in height and 2.44 m in width. It can also make a curved laminate and be able to implement bulletproof glass, SGP glass, according to international quality specifications.

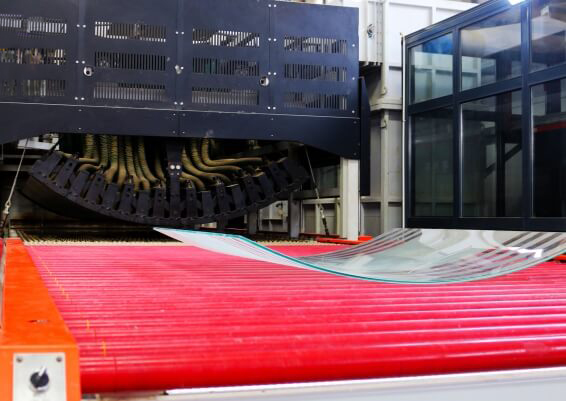

Tempered Glass Line

It is the newest line in the Middle East, as it can deal with Low-E Glass as well as the ability to carry out large sizes up to 5 meters in height and 2.4 meters in width, It also has the latest quality measurement methods to avoid curvature and visual distortion.

Curved Glass Line

Capable to executing tempered curved glass up to size 5000mm x 2400mm.

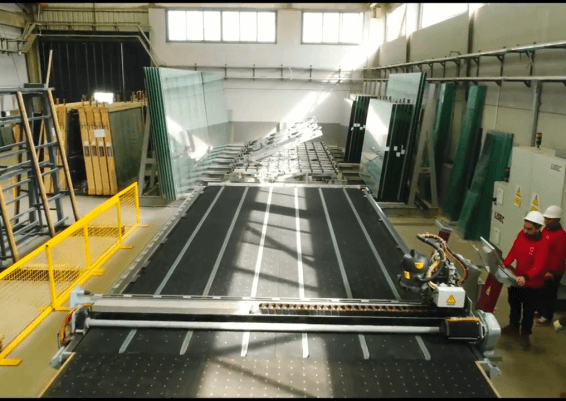

Cutting Glass Line

Fully automatic machine designed to cut special flat glass using wheel cutting technology using edge remover to remove reflector layer in the edge area accordance to international quality standards in the field of manufacturing double glazing.